Hot Blast HB1520 Wood Furnace

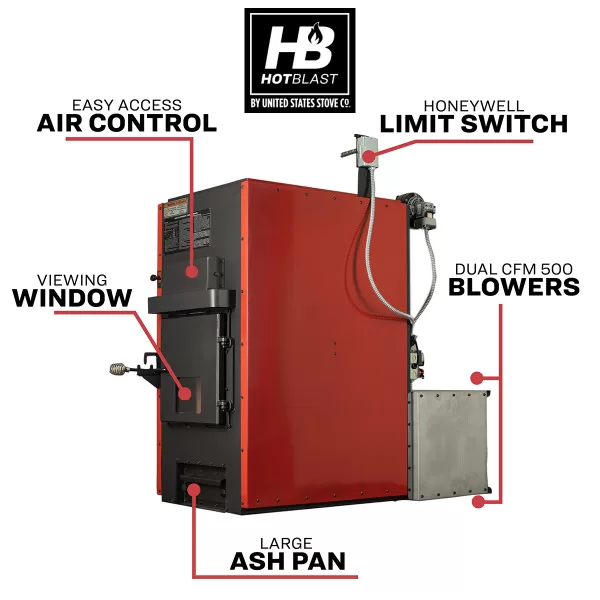

The Hot Blast HB1520 by US Stove is a wood burning furnace designed to use in conjunction with your existing HVAC ductwork. With twin 500 CFM blowers and up to 180,000 BTUs, it is designed to heat a home up to 3,500 Sq. Ft. Its heavy duty cast-iron door with a glass viewing front gives out the ambience of a flame without compromising efficiency. The open plenum allows for easy installation and with a built in ash-pan and firebrick line combustion chamber, the HB1520 is a great option for heating larger spaces in the furnace category. The Hot Blast HB1520 EPA certified furnace exceeds 75% efficiency and qualifies for the 30% IRS 25C Residential Energy Tax Credit.

Model #: HB1520

Additional Information:

- Heavy Duty cast-iron door with viewing window

- Heats up to 3,500 Sq Ft of living space with 180,000 BTUs

- EPA Certified & 75% Efficiency Rating

- Accepts logs up to 23″ and easy to load

- Qualifies for IRS 30% 25C Residential Energy Tax Credit

- Firebrick lined to boost efficiency and heating capacity

- Built in ash pan for easy clean up

- Recommended installation by NFI Certified Installer (USA) or WETT Certified Installer (Canada)

- Dual blowers provide maximum heat output

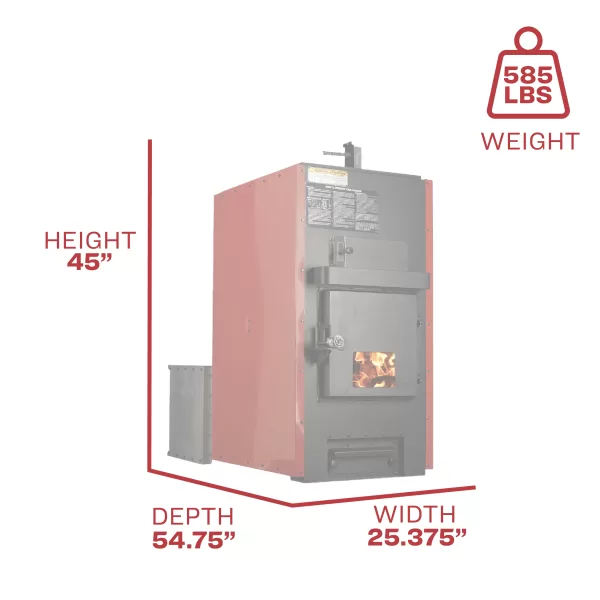

| Assembled Width (in) | 23.375 |

| Package Weight | 585 |

| Package Width | 27.5 |

| Package Height | 50 |

| Assembled Depth (in) | 54.75 |

| Package Depth | 36.5 |

| Assembled Height (in) | 45 |